How Additive Manufacturing is Transforming Production

Introduction

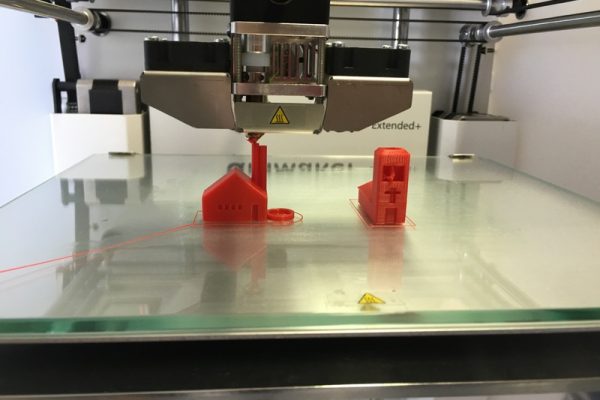

You’ve probably heard of additive manufacturing, but do you really know what it is? Also known as 3D printing, this fascinating technology is constantly evolving. In this article, we’ll explore together how additive manufacturing is revolutionizing the world of manufacturing production.

Advantages of Additive Manufacturing

Mass customization

One of the most exciting aspects of additive manufacturing is the ability to create unique products, tailored to the specific needs of each customer. Gone are the constraints of traditional molds and tooling! With 3D printing, you can give free rein to your creativity and offer highly personalized products.

Design Optimization

If you’re frustrated by the limitations imposed by conventional manufacturing methods, additive manufacturing opens up a whole new world! You can create complex, optimized shapes, and integrate never-before-seen features right from the design stage.

Cutting lead times and costs

If you’ve ever worked on the development of a new product, you know how time-consuming and costly prototyping can be. Additive manufacturing changes all that: prototypes can be made quickly, different options can be tested, and design iterations can be accelerated. No more costly tooling and tedious intermediate steps!

Secure production with Vistory

The MainChain solution, created by Vistory, revolutionizes on-demand production by securing the process. Indeed, MainChain provides access to a new production method, enabling a more efficient response to specific needs, while reducing inventories and lead times. Thanks to its private Blockchain, MainChain ensures the integrity and conformity of drawings for parts produced using 3D printing. It also offers complete traceability of operations, while guaranteeing full protection of the manufacturer’s industrial property.

The Challenges of the Transition to Additive Manufacturing

Volumes

3D printing can help you meet many challenges. Indeed, even if this technology is not yet suitable for so-called “assembly-line” production methods, 3D printing enables you to produce on demand, and thus meet the specific and precise needs of each part. Beyond the agility and resilience that this solution provides, additive manufacturing opens the way to responsible, measured production.

Integration into existing processes

Adopting additive manufacturing means adapting your workflows, developing new skills, and managing the transition from familiar methods. Vistory can support you in this transition, thanks to our years of experience in 3D printing, and our passionate teams will accompany you in your design projects. As every request is different and requires a personalized response, Vistory will guide you towards the best choice.

Future Opportunities in Additive Manufacturing

Automation and digital integration

To fully exploit the potential of additive manufacturing, it will need to be coupled with other cutting-edge technologies, such as automation and robotics. Eventually, we can imagine end-to-end integrated digital production systems, in which additive manufacturing plays a central role. It’s an exciting challenge for engineers and developers!

DECENTRALISED, ON-DEMAND PRODUCTION

Finally, additive manufacturing opens the way to new, more flexible and decentralised production models. Rather than concentrating production in large factories, we will be able to manufacture locally, as close as possible to requirements. And thanks to on-demand production, there’ll be no more dormant stocks or complex logistics!

Mobile Clinics

Vistory’s Mobile Clinics solution, developed to deal with operational, health or climatic emergencies, offers a secure and agile response to meet component production or construction needs as closely as possible. Mobile Clinics are also ideally suited to meet the production, construction or accelerated repair challenges faced by manufacturers and builders. This solution enables parts to be produced as quickly as possible to restore essential equipment, with priority given to in-situ processes.

This solution enables parts to be produced as quickly as possible to restore essential equipment, with priority given to in-situ processes.

Conclusion

We have seen the extent to which additive manufacturing is profoundly transforming manufacturing production. Customization, design optimization, cost and lead time reduction… The benefits are numerous and promising.

Future opportunities are immense, with the development of new materials, automation and the emergence of decentralized production models. To remain competitive, companies need to adapt now and adopt these cutting-edge technologies.

What about you? Have you already experimented with additive manufacturing in your business or personal projects? I’d love to hear your feedback!

Our solutions

Our company