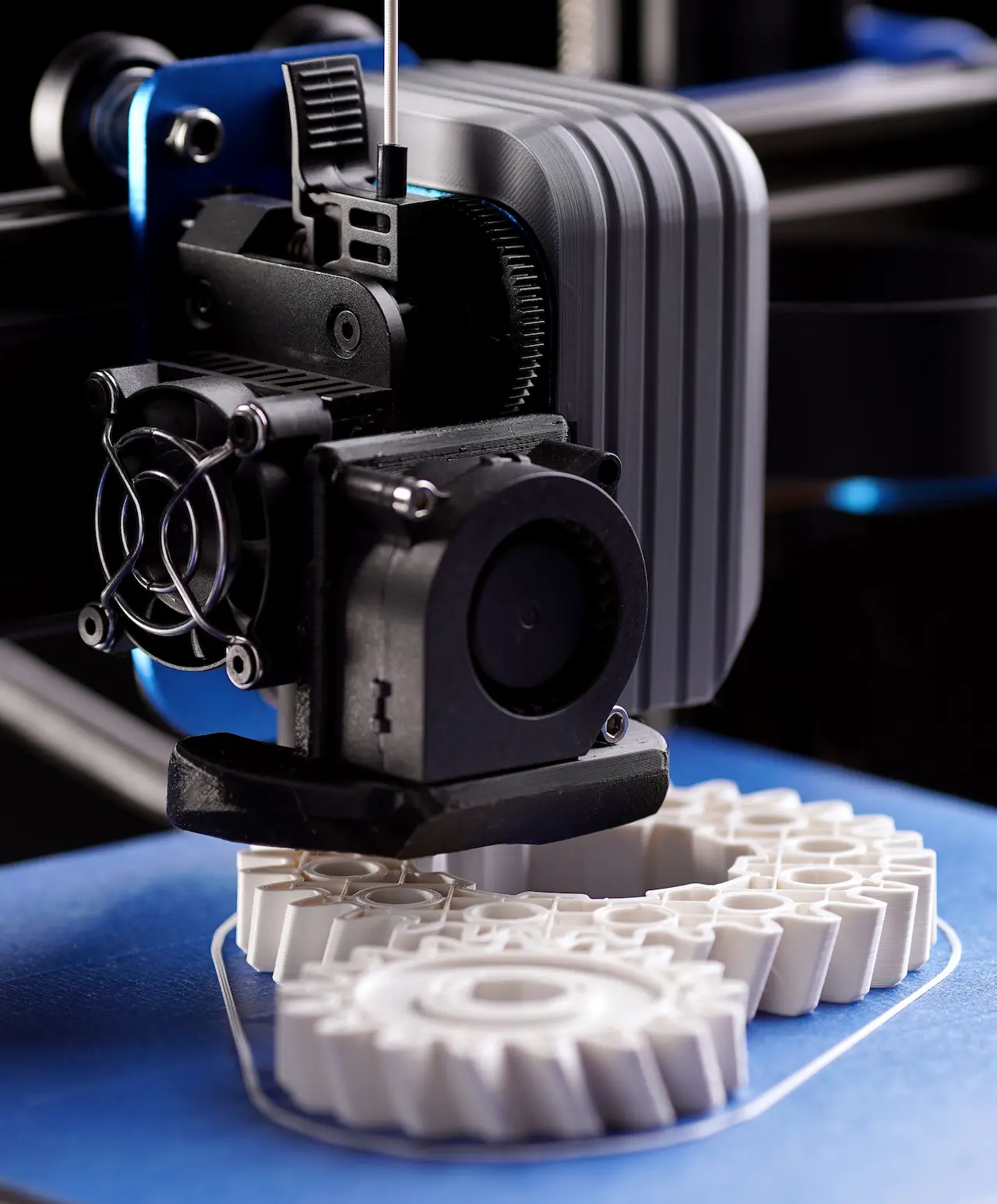

Manufacturing unavailable parts

FastRepro allows you to study the feasibility of your parts in 3D printing and the possibilities of remanufacturing that will meet your expectations and constraints. Vistory supports your choices and delivers your parts within 3 weeks.

Producing just what is needed

Often, for a single faulty part, the commercial offer imposes the purchase of a complete set. The cost will therefore be proportionally high and the ecological impact very negative. With FastRepro and 3D printing you will only manufacture what you need.

Bringing your 3D files to life in a few clicks

With FastRepro you can estimate and order the production of your 3D files in various materials. Through our network of partners, we offer access to a wide range of manufacturing solutions, worldwide and completely securely through MainChain.