Reducing production downtime

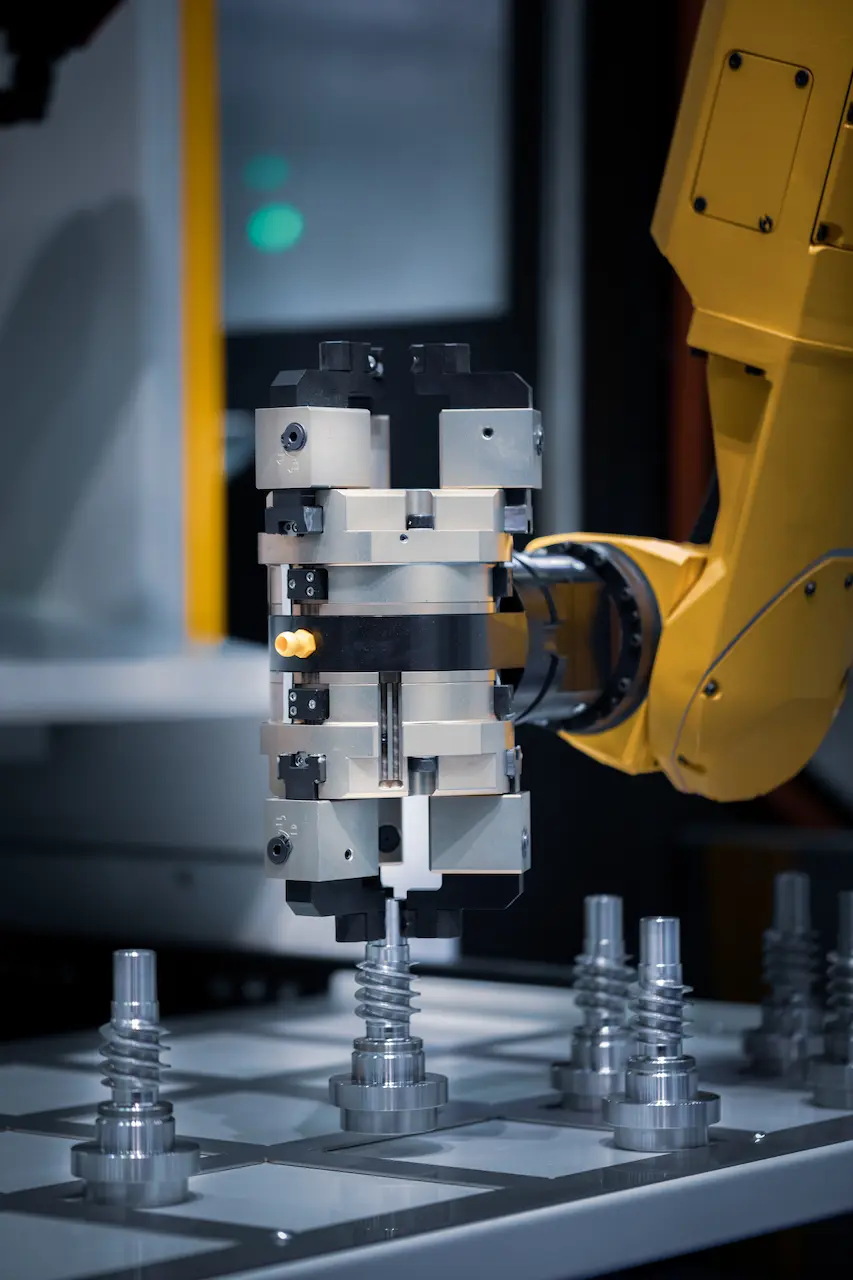

Vistory supports maintenance units in finding solutions to remanufacture obsolete parts needed to operate equipment. MainChain allows teams to access a secure digital warehouse that allows them to manufacture parts on demand to meet operational production requirements.

Sustaining customer satisfaction

The security provided by MainChain and the possibilities offered by additive manufacturing make it possible to offer spare parts for old products whose mass production has been stopped, without the costs of a traditional production line, nor those of a dormant physical stock which may be destined for destruction.

Moving safely into on-demand production

Beyond the security provided by the MainChain solution, Vistory's services support you from the first stages with FastRepro: feasibility, selection of parts, remanufacturing, up to the implementation of a dedicated production unit, Cybertron.